Mobile Concrete Batching Plant

As a prominent and leading exporter from Ahmedabad, we offer Mobile Concrete Batching Plants, Compact Concrete Plants, Portable Concrete Plants, Mobile Concrete Mixers, and Mobile Batching Plants at affordable and competitive rates.

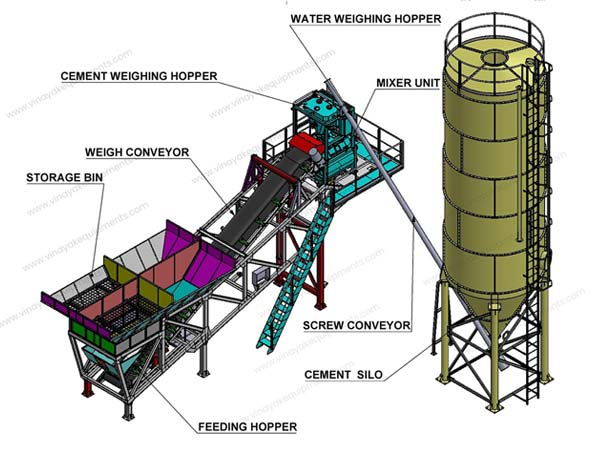

Compact Concrete Plant

Request CallbackStarting from $60,000

| Model | CCBP - 30 |

| Capactiy | 1125 / 750 |

| Aggregate Storage System | Compartment Bin |

| Mixer Unit Capacity | 1125 / 750 |

| PLC Based Control Panel | Yes |

| Water Hopper Capacity | 200 Ltr. |

| Loadcell | 1 No |

| Mixer Unit Type | Twin Shaft Mixer Sicoma |

| Brand | Vinayak |

- Quick and easy installation and operation 3 to 4 days to start concrete production and one day for disassembling.

- The plant can produce Dry Mix Concrete also.

- Less space required for Installation due to its compact design.

- Less foundation costs ( 80% less than conventional stationary concrete batching plants)

- Mobility System for Concrete Plant with king pin attachment and pneumatic braking system. Single chassis mounting of the whole plant. ( Optional )

- Less transportation costs.

- Minimized concrete transportation costs.

- The plant comes with fully prewired with Junction Box ( Complete with internal cabling).

- Cement Storage Silo

- Silo Accessories.

- Silo Feeding System.

- Admixture Dosing System.

- Water Connection.

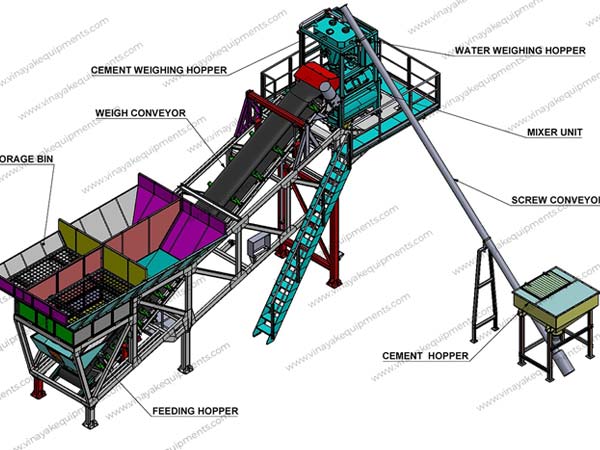

Portable Concrete Plant

Request CallbackStarting from $60,000

| Concrete Output | 30 m3 |

| Capacity | 1125 / 750 |

| Cement / Flyash Hopper Capacity | 500 kgs. |

| Vibrator Motoor | 1 No. |

| Cement Screw conveyor with Bag Hopper | Yes / 50 Bags |

| PLC Based Control Panel | Yes |

| Brand | Vinayak |

- Compartment type aggregate storage bins

- Weighing bin and conveyor

- Cement bag filling hopper with screw conveyor

- PLC based control panel with HMI display

- Cement weighing hopper

- Additive weighing container

- Water weighing hopper

- Air compressor

- Cement storage silo

- Silo accessories

- Silo feeding system

- Admixture dosing system

- Water connection system

We believe that customer satisfaction comes from products that perform efficiently and reliably with minimal downtime. We follow stringent quality assurance checks at every stage, starting from raw material selection. Our self-motivated workforce ensures that each product meets high quality standards, with every employee taking responsibility as a quality inspector.

Design & EngineeringOur products are engineered based on strong fundamental principles, supported by past experience, field feedback, and continuous innovation. Application-oriented design and practical engineering solutions form the core of our product development process.

Mobile Concrete Mixer

Request CallbackStarting from $60,000

| Automation Grade | Automatic |

| Usage/Application | Ready Mix Concrete |

| Model No. | CCBP-30, CCBP-30 |

| Mixer Type | Twin Shaft Mixer |

| Chassis | Heavy Duty |

| Brand | Vinayak |

- Production Capacity: 5 Units

- Delivery Time: 30 Days

- Packaging Details: Standard Export Packing

Mobile Batching Plant

Request CallbackStarting from $60,000

| Capacity | 1125 / 750 |

| Usage/Application | Ready Mix Concrete |

| Mixer Type | Twin Shaft Mixer |

| Chassis | Heavy Duty |

| Brand | Vinayak |

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer), Balance Against Delivery

- Port of Dispatch: Mumbai, India

- Production Capacity: 20 m³/h – 60 m³/h (Customizable)

- Delivery Time: 3–4 Weeks

- Installation Type: Mobile / Trailer Mounted

- Hassle-free operation

- High mobility and portability

- Quick and easy setup

- Compact and space-saving design

- Accurate batching and weighing system

Mobile Concrete Batching Plant

Request CallbackStarting from $60,000

| Automation Grade | Automatic |

| Usage/Application | Ready Mix Concrete |

| Model No. | CCBP-30, CCBP-30 |

| Mixer Type | Twin Shaft Mixer |

| Chassis | Heavy Duty |

| Brand | Vinayak |

- Concrete batching plant available in 30 CM per hour capacity

- Aggregate stored in inline bins

- Aggregate weighing suspended on four “S” type load cells for higher accuracy

- Independent weighing system for aggregate, cement, water, and additive

- Fully automatic electronic operation with PLC/PC control

- Minimal installation time due to modular design

- Available with single shaft, twin shaft, pan, or planetary type mixers

- Reliable, fast, and accurate electronic weighing system for major inputs

- Complete service support with technical assistance and spare parts backup

- Production Capacity: 5 Units

- Delivery Time: 30 Days

- Packaging Details: Standard Export Packing